An ambient light sensor in service for five years that I have on the top floor of a building recently drowned. Well, that's because water accumulated in the aluminum can which housed it. And the reason water accumulated was that the half-inch aluminum angle that was propping the can up got bent back by storm winds. Below are photos I took back in 2009 of the flimsy aluminum can and anodized aluminum post..

Here's the poor circuit board all corroded.

I made sure the new sensor housing would be robust and would not suffer the same fate. I used scrap pieces of 1/16" x 1-1/4" square tubing, 3/32" x 1" angle, 3/32" x 1-1/2 angle, 3/32" x 2" angle and a short piece of 1" flat bar. for the post that would support the housing to the catwalk. All the parts were MIG welded together. The housing itself is the box of a very old and burnt transformer. And by scorched I mean the entire unit had been in a fire.

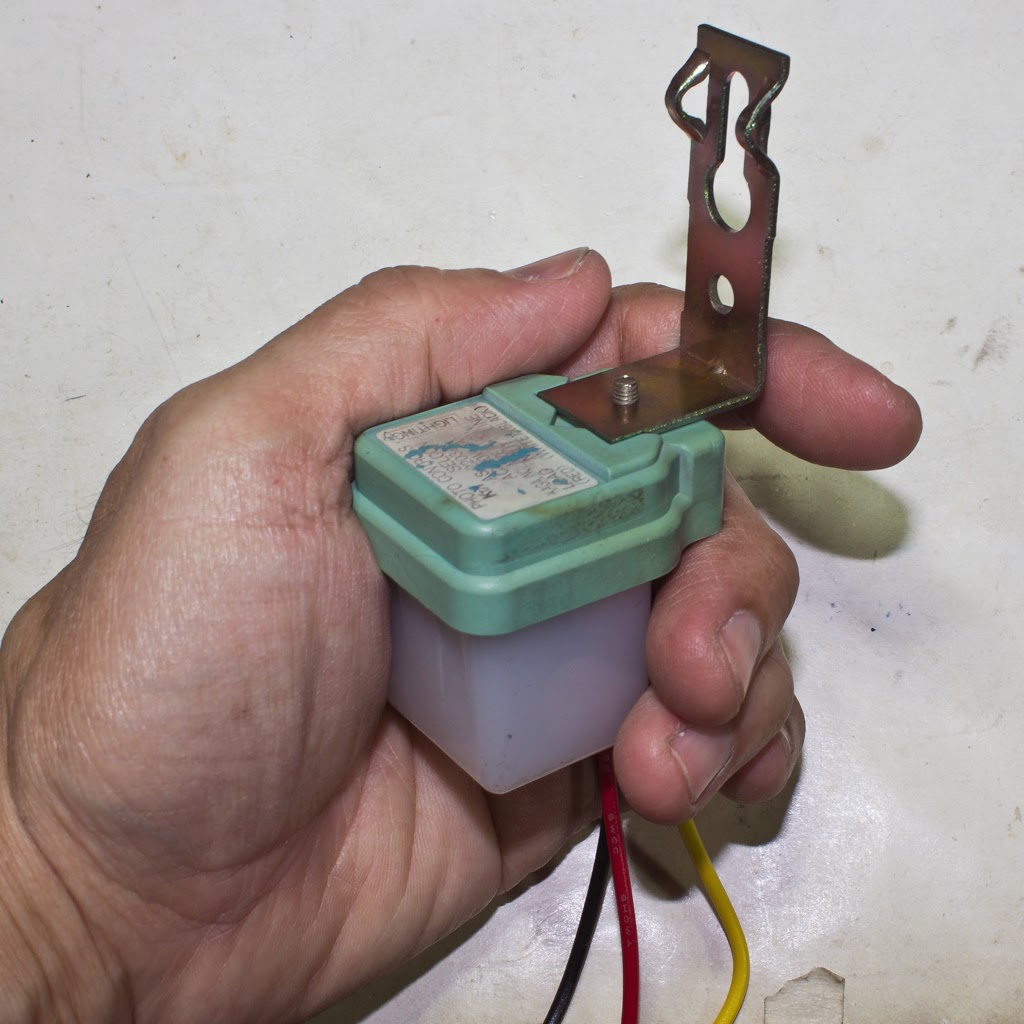

Here's the new sensor. Am still using the same Selcon brand plastic housing. The Selcon circuit is somewhere in my junk box.

Sensor and new housing installed. The housing is fastened to the post with only one stainless 3/8" bolt. This allows the housing to be oriented in any direction.

The square tubing is clamped to the catwalk railing with two stainless U-bolts. The cable to the sensor is fastened to the catwalk using nylon cable ties.

A Stab at Fab

Friday, October 24, 2014

Tuesday, September 23, 2014

Wind chime build

My goal in this build has been to use second hand materials as much as possible and items that were just lying around the house. I think I've achieved that objective. The only brand new stuff that went into this build were the black paint, varnish and some 12 inches of string.

The chimes are made out of 1-1/4" square tubing with 1/16" wall thickness. Tube lengths are 20", 17-7/8", 16-3/8", 14-5/8". I had a 20" tube lying around so I chose that as the longest piece and computed the lengths for the remaining three (and rounded them off to the nearest 8th inch). Supposedly and theoretically, given these lengths, they should play the notes C, E, G, B. The fact that these are not new tubing, with welds and dents and holes means there will be variations in the sound they produce. The nodes (point at which the tube is not vibrating) are located at 22.4% from the ends of the tube. These are where the holes have been drilled and the tubes hung by.

The sail / windcatcher had been a headache since the beginning. Tried several types of materials after I hung this thing up on the eaves: plastic film from a sack, plastic roofing material, cardboard. The latter was the most effective but it's hardly rain-proof. Then while having lunch it hit me that the floppy disks I have lying around would probably be a perfect choice. If one wasn't enough I could daisy chain them to increase the surface area. Turned out to be a great idea. The disks are light and waterproof (except for the liner inside I think).

References:

http://www.phy.mtu.edu/~suits/windchime.html

http://home.fuse.net/engineering/Chimes.htm

The chimes are made out of 1-1/4" square tubing with 1/16" wall thickness. Tube lengths are 20", 17-7/8", 16-3/8", 14-5/8". I had a 20" tube lying around so I chose that as the longest piece and computed the lengths for the remaining three (and rounded them off to the nearest 8th inch). Supposedly and theoretically, given these lengths, they should play the notes C, E, G, B. The fact that these are not new tubing, with welds and dents and holes means there will be variations in the sound they produce. The nodes (point at which the tube is not vibrating) are located at 22.4% from the ends of the tube. These are where the holes have been drilled and the tubes hung by.

The sail / windcatcher had been a headache since the beginning. Tried several types of materials after I hung this thing up on the eaves: plastic film from a sack, plastic roofing material, cardboard. The latter was the most effective but it's hardly rain-proof. Then while having lunch it hit me that the floppy disks I have lying around would probably be a perfect choice. If one wasn't enough I could daisy chain them to increase the surface area. Turned out to be a great idea. The disks are light and waterproof (except for the liner inside I think).

References:

http://www.phy.mtu.edu/~suits/windchime.html

http://home.fuse.net/engineering/Chimes.htm

Wednesday, August 27, 2014

Practicing with flux cored wire

Need to do some welding outdoors so am trying to get the hang of flux cored. Frankly, I'd like to stay away from gasless welding.

Sunday, July 13, 2014

Step ladder with spring-loaded casters

A couple of months ago my sister commissioned me to build a step ladder tailor-made for her kitchen so she could reach the top shelves of the overhead cabinets. More importantly she wanted a way for her reckless 5-yr old to safely reach the cabinet (to get his juice bottle) without scaling the countertop and precariously making his way up (drumming in a list of don'ts just hasn't worked).

I didn't want to make just another run of the mill ladder. I wanted a sleek design that didn't look like just another a ladder. The original design did not include the 4 feet extending diagonally off the bottom of the ladder. But I had to add them because the ladder had the tendency to tip over whenever a person shifted their weight close to or over the railings. I implored and pleaded with physics and gravity, but they just wouldn't make an exception for this project. Much as I don't want those feet--they ruin the look--they're essential for safety.

I also wanted a ladder that both kids and adults could move with ease. My sister suggested putting two non-swiveling casters so that the ladder could be tilted on those casters and then wheeled into place like a hand truck. That was fine with adults but I was concerned--given the height and weight of the all-steel ladder--that that would result in accidents when my nephews started rolling the ladder. No, that option just wasn't kid-friendly. And so I decided to use spring-loaded casters.

The problem is, I couldn't find any hardware store selling such casters. Hence, I was forced to design one that I could, with my paltry fab skills, build on my own. I couldn't think of an easy way of putting the spring directly on the caster so I decided on using a chassis to bolt the casters on and then mounting the springs on half-threaded bolts to function as guide pins which would mate the chassis to the ladder.

The frame of the ladder including the feet is made from 1/16 x 1" square tubing; the steps, from 1/16 x 1 x 2" tubing; the chassis or "H-frame" for the casters, from 1" angle and 1/16 x 1" tubing. The ladder is 48" high, 17" wide and 14" deep, excluding the feet and caster system. The steps are 9" apart vertically, thus the topmost step is 27" from the ground.

I was able to purchase a spring about 20" in length and about half an inch in diameter. I did some crude tests with a weighing scale to measure its displacement versus force characteristic. For this particular spring it came out to about a quarter inch per kilogram. The ladder was around 13 kg so each of the four springs would be bearing a little over 3 kg. I eventually ended up cutting approximately 2-1/4" lengths of springs.

For the guide pins I used 3/8" x 3-1/2" galvanized hex head half-threaded bolts that have a 2-1/4 inch length that isn't threaded. These weren't ideal but the hardware didn't have any 3/8 bolt which had 2-1/2 to 2-3/4" of non threaded section.

Among the mostly black, shoddy-looking casters in the hardware, I found gray-colored rubber 2" swivel casters that really look good and whose color would match the finish of the ladder

As can be seen in the photo below I temporarily tack welded the H-frame the tubings which needed to be drilled so that the holes would register as precisely as I could make them.

For the majority of the welds I used MIG--am far more comfortable with that process. But I had a new TIG machine and so used it for just about all of the butt welds, except for the steps of the ladder which were all MIG welded--I was just too ill-confident and lazy to TIG weld them.

After grinding down all the non-fillet welds and cleaning the metal I painted it with a coat of red oxide primer. Sanded it afterwards in the hopes of getting a shinier finish with the topcoat. Mys sister's kitchen cabinets are in gray and orange so I painted the ladder likewise.

I didn't want to make just another run of the mill ladder. I wanted a sleek design that didn't look like just another a ladder. The original design did not include the 4 feet extending diagonally off the bottom of the ladder. But I had to add them because the ladder had the tendency to tip over whenever a person shifted their weight close to or over the railings. I implored and pleaded with physics and gravity, but they just wouldn't make an exception for this project. Much as I don't want those feet--they ruin the look--they're essential for safety.

I also wanted a ladder that both kids and adults could move with ease. My sister suggested putting two non-swiveling casters so that the ladder could be tilted on those casters and then wheeled into place like a hand truck. That was fine with adults but I was concerned--given the height and weight of the all-steel ladder--that that would result in accidents when my nephews started rolling the ladder. No, that option just wasn't kid-friendly. And so I decided to use spring-loaded casters.

The problem is, I couldn't find any hardware store selling such casters. Hence, I was forced to design one that I could, with my paltry fab skills, build on my own. I couldn't think of an easy way of putting the spring directly on the caster so I decided on using a chassis to bolt the casters on and then mounting the springs on half-threaded bolts to function as guide pins which would mate the chassis to the ladder.

I was able to purchase a spring about 20" in length and about half an inch in diameter. I did some crude tests with a weighing scale to measure its displacement versus force characteristic. For this particular spring it came out to about a quarter inch per kilogram. The ladder was around 13 kg so each of the four springs would be bearing a little over 3 kg. I eventually ended up cutting approximately 2-1/4" lengths of springs.

For the guide pins I used 3/8" x 3-1/2" galvanized hex head half-threaded bolts that have a 2-1/4 inch length that isn't threaded. These weren't ideal but the hardware didn't have any 3/8 bolt which had 2-1/2 to 2-3/4" of non threaded section.

Among the mostly black, shoddy-looking casters in the hardware, I found gray-colored rubber 2" swivel casters that really look good and whose color would match the finish of the ladder

As can be seen in the photo below I temporarily tack welded the H-frame the tubings which needed to be drilled so that the holes would register as precisely as I could make them.

For the majority of the welds I used MIG--am far more comfortable with that process. But I had a new TIG machine and so used it for just about all of the butt welds, except for the steps of the ladder which were all MIG welded--I was just too ill-confident and lazy to TIG weld them.

After grinding down all the non-fillet welds and cleaning the metal I painted it with a coat of red oxide primer. Sanded it afterwards in the hopes of getting a shinier finish with the topcoat. Mys sister's kitchen cabinets are in gray and orange so I painted the ladder likewise.

|

| Te spring-loaded caster system. The two 1" square tubing pieces will eventually be welded to the ladder |

|

| Letting the paint dry completely before installing the caster system. Black rubber end caps are installed on the feet |

Monday, June 9, 2014

TIG/Stick welder

Recently bought this China-made, unheard-of brand inverter type DC power supply for GTAW/SMAW

Specs:

* 10 to 200A (who knows how accurately it can reach those upper/lower limits).

* 60% duty cycle at 200A, 100% at around 150A.

* TIG polarity fixed at DCEN.

* Continuous/pulse TIG (still no idea what the frequency range is).

* No preflow; postflow fixed at around 4sec.

* No upslope control; downslope adjustable from 0 to 5sec (though it doesn't feel like it runs that long).

* 2T/4T setting but latter is pseudo 4T -- pressing the torch switch turns the arc on, arc remains lit when switch is released; pressing it again and releasing it turns the arc off (if downslope is set to >0 then the arc decays accordingly).

* No foot pedal and won't work with one; strictly on/off switch activated.

* High frequency start (wouldn't have bought if it didn't have HF)

* Digital readout only displays main amps setting.

* Air cooled torch.

* DINSE connector for ground and SMAW leads.

* Integrated gas and electrical connector for TIG torch.

* Internal solenoid for shielding gas flow.

First time to TIG weld so am still at the bottom of the learning curve. It's not easy at all. Particularly with my ever deteriorating eyesight. Am specially having problems with stainless steel. Judging from the color of the welds on the thin gauge scraps I'm using, I am overheating the metal even with the amps turned way down low. I've had better luck with mild steel.

Specs:

* 10 to 200A (who knows how accurately it can reach those upper/lower limits).

* 60% duty cycle at 200A, 100% at around 150A.

* TIG polarity fixed at DCEN.

* Continuous/pulse TIG (still no idea what the frequency range is).

* No preflow; postflow fixed at around 4sec.

* No upslope control; downslope adjustable from 0 to 5sec (though it doesn't feel like it runs that long).

* 2T/4T setting but latter is pseudo 4T -- pressing the torch switch turns the arc on, arc remains lit when switch is released; pressing it again and releasing it turns the arc off (if downslope is set to >0 then the arc decays accordingly).

* No foot pedal and won't work with one; strictly on/off switch activated.

* High frequency start (wouldn't have bought if it didn't have HF)

* Digital readout only displays main amps setting.

* Air cooled torch.

* DINSE connector for ground and SMAW leads.

* Integrated gas and electrical connector for TIG torch.

* Internal solenoid for shielding gas flow.

First time to TIG weld so am still at the bottom of the learning curve. It's not easy at all. Particularly with my ever deteriorating eyesight. Am specially having problems with stainless steel. Judging from the color of the welds on the thin gauge scraps I'm using, I am overheating the metal even with the amps turned way down low. I've had better luck with mild steel.

They say that a newbie shouldn't train on a cheapo portable AC buzz box because it's just going to be a maddeningly frustrating experience that could eventually lead to a fear of or revulsion to stick welding. Well, I've proven that warning is indeed true. When I tried out this welder's stick mode I was instantly--as in within a second of touching the electrode to the work piece--blown away by the ease of starting an arc and laying down a bead. The arc was smooth as silk. Let me just repeat that for unmistakable emphasis: The arc, the sound it made and the puddle were soooo lusciously smooth and creamy. No electrode-sticking problem at all with the 2.4mm E6013 @80A (which was the very first setting I used when I fired up the machine). After using up half the rod, I switched over to 2.4mm E6011. Couldn't strike an arc--kept sticking. So I bumped the amps up to 90 and bingo! Got an arc going without a hitch even when I wasn't feeding the rod fast enough (because 6011 burns fast!) and had to relight on the fly a couple of times. Did not at all get a charred flux coating on the remaining rod as I did months back on the buzz box. Used up three quarters of the stick and then swapped it out for a 3.2mm stainless rod. Dialed the amps to 110. Laid out a bead on the very first attempt with no flame-out issues.

If there were any problems, it had to do with my travel speed, arc length, electrode angle and amp settings which I have yet to fine tune. (All tests on DCEP, on 3/16" mild steel plate. Ground setup employs my McGveryism of using copper coated steel wool as interface between the ground clamp and the workpiece for very reliable electrical contact.)

Without any hyperbole I can honestly say that using this inverter has rectified (ha! pun intended) my fear of SMAW.

Tuesday, April 15, 2014

Getting a better electrical ground for welding

|

| Label says it's made in China |

I found the above copper wool in a store and snapped up a pack. When I reached home the first thing I did was to grab a big magnet and check whether this is pure copper or just plated. What do you think? Well, it clung to the magnet but not as strongly as ordinary steel so I suspect the base metal is some type of stainless steel.

Well copper or not, metal wool makes an excellent "sponge" to create lots of small good contact points between the ground clamp and the workpiece to be welded or the welding table. I now use the copper plated wool whenever I weld. It gives me greater confidence while welding in that it completely eliminates one variable--bad ground connection--when the weld isn't going well.

Couple of months ago I hacked my MIG ground clamp by cutting and stripping several feet of AWG#14 solid copper wire, folding it at the middle and then looping that around the screw that secures the lug of ground cable and then finally winding the rest of the wire around one of the jaws of the clamp. The idea is to have the copper get clamped onto the workpiece. The wool now further increases the area of contact thus further decreasing electrical resistance.

This wool is rather course and I would think that a finer one would be even more effective. And given a finer grade's greater pliability, it can be folded and pressed/crushed far easier than this one I'm using.

Hat tip goes to Jody Collier of weldingtipsandtricks.com. In one of his vids he talks about using flexible heavy gauge welding cable and stripping the insulation off and using that with the ground clamp to increase the surface area in the interface between clamp and work piece. Jody has some of the best if not the best welding vids on Youtube. His tips are beyond valuable. Go watch and subscribe.

Monday, April 14, 2014

My MIG welder

I got this CIGWELD WeldSkill 150 second hand late last year. The wire speed control is infinitely variable (you can set it to 7.75 for instance) but the voltage control has detents which allows only 4 settings. The machine works very well for 1/16" thick steel and thicker. However, I still can't get it to properly weld thinner gauge sheet steel. I can't get good continuous welding with wire speeds lower than #7 even with voltage turned down to its lowest setting of #1. Not yet sure why.

|

| Auto-darkening helmet in the background and an AC stick welder which I haven't used in months |

|

| Load with a new spool of 5kg 0.9mm flux cored wire |

|

| Red and black wires need to be swapped depending on whether you're using flux cored or solid wire |

LPG bottle dollies

The LPG bottle we use has an empty weight of around 1kg and filled weight of around 25kg. So lifting the cylinder isn't really that good for aging backs. I usually lay it on a thick rag and drag the cylinder when I have to move it. Gets the job done with much less strain but it isn't the most efficient nor elegant method. I recently saw a round dolly at a home depot and instantly decided to make one myself. It was one of those "why didn't I think of that?!" moment. Ah well.

With a good number of second hand 1/16" x 1-1/4" square tubing (but actually 1-3/16") laying around I chose this as the material of choice for the dolly. I cut four pieces of 9-5/8" lengths with 45-degree miter cuts using a 14" chop saw. The bottom of the gas bottle has a nominal outer diameter of 12" and inner diameter of 10". The diagonal of a square is equal to L√2, where L is the length, so with each side 9-5/8" the diagonal comes out to around 13-5/8" which is long enough to accommodate the 12" diameter of the cylinder.

2-1/2" lengths of angle irons were cut and welded to the inner corners of the square. These prevent the bottle from slipping off or from being knocked off the dolly. One side (the top side) of each angle iron piece is miter cut at 45 degrees. This diagonal eases mounting of the bottle on the dolly since if the cylinder lands on that incline it can slide down (or push the dolly off a bit) so the bottom of the bottle lands on the corners of the platform.

1" diameter casters were tack welded to the dolly. Their mounting plates were simply too thin and had too little surface area to weld continuously so they're held by a good number of tacks. Had a problem with one of the casters--it won't swivel freely anymore. A dingleberry must've landed in the ball bearings while I was MIG welding the caster to the frame. Lesson learned--shield moving parts and protect sensitive components from spatter.

Photos shown it already built and painted with red oxide primer.

Brought the dolly to my sis when I visited her and since she liked it and found it useful I left it with her. Can't find any photos of it after painting it black. Must've forgotten to shoot one.

Since I need a dolly for myself I had to build another one. But I found the aesthetics of the above design more than wanting. Looking at it puts a pout on my face. Surely there are far better looking designs I told myself, although I had to work within constraints--my greenhorn abilities, ease/difficulty of fabrication,. limited equipment (no tube bender, press brake, band saw, etc.), and materials available in the garage.

Still using 1-1/4" square tubing, I cut one 14" and two 6-3/8" pieces. MIG welded the two latter to the center of former to form an X. Using a 4" angle grinder I ground the butt joints flush with the surface while leaving the fillets as they are. Used the same-sized casters as with the first dolly but with nylon wheels. Black plastic end caps close the holes on all four ends.

Because of my experience with the first dolly--having a dingleberry or two land and weld themselves in the bearings in one of the caster's swivel mechanism--I used masking tape and some scrap paper to encapsulate each of the casters to prevent any spatter from getting into where they shouldn't. The paper did catch fire a couple of times and I put it out simply by patting it with my leather-gloved hands. After tack welding the casters onto the frame I removed all the (partially burned) tape and paper and wrapped the casters again right before painting. One coat of red oxide primer and two coats of yellow quick dry enamel.

Except for the general X shape, am still not satisfied with this second build. I was working within material constraints. I'd rather use 1/8" x 2" flat bars as the platform and then weld on 1/8 x 1" flat bars as vertical supports, thus forming a T section. And I find the 1" casters too small for ease of rolling and too flimsy for the heavy load. 1-1/2 to 2" diameter wheels would be far better. And instead of casters with mounting plates that have 4 holes for screws, I'd use something like these and have those vertical pins go under the LPG bottle to secure it in place on the dolly. And if it isn't yet obvious, the tack welds on the casters are absolutely godawful! They're hideous. I'd rather not resort to welding them unless they've got much beefier steel plates.

Design #1: Square Frame

With a good number of second hand 1/16" x 1-1/4" square tubing (but actually 1-3/16") laying around I chose this as the material of choice for the dolly. I cut four pieces of 9-5/8" lengths with 45-degree miter cuts using a 14" chop saw. The bottom of the gas bottle has a nominal outer diameter of 12" and inner diameter of 10". The diagonal of a square is equal to L√2, where L is the length, so with each side 9-5/8" the diagonal comes out to around 13-5/8" which is long enough to accommodate the 12" diameter of the cylinder.

2-1/2" lengths of angle irons were cut and welded to the inner corners of the square. These prevent the bottle from slipping off or from being knocked off the dolly. One side (the top side) of each angle iron piece is miter cut at 45 degrees. This diagonal eases mounting of the bottle on the dolly since if the cylinder lands on that incline it can slide down (or push the dolly off a bit) so the bottom of the bottle lands on the corners of the platform.

1" diameter casters were tack welded to the dolly. Their mounting plates were simply too thin and had too little surface area to weld continuously so they're held by a good number of tacks. Had a problem with one of the casters--it won't swivel freely anymore. A dingleberry must've landed in the ball bearings while I was MIG welding the caster to the frame. Lesson learned--shield moving parts and protect sensitive components from spatter.

Photos shown it already built and painted with red oxide primer.

Brought the dolly to my sis when I visited her and since she liked it and found it useful I left it with her. Can't find any photos of it after painting it black. Must've forgotten to shoot one.

Design #2: X-Frame

Since I need a dolly for myself I had to build another one. But I found the aesthetics of the above design more than wanting. Looking at it puts a pout on my face. Surely there are far better looking designs I told myself, although I had to work within constraints--my greenhorn abilities, ease/difficulty of fabrication,. limited equipment (no tube bender, press brake, band saw, etc.), and materials available in the garage.

Still using 1-1/4" square tubing, I cut one 14" and two 6-3/8" pieces. MIG welded the two latter to the center of former to form an X. Using a 4" angle grinder I ground the butt joints flush with the surface while leaving the fillets as they are. Used the same-sized casters as with the first dolly but with nylon wheels. Black plastic end caps close the holes on all four ends.

Because of my experience with the first dolly--having a dingleberry or two land and weld themselves in the bearings in one of the caster's swivel mechanism--I used masking tape and some scrap paper to encapsulate each of the casters to prevent any spatter from getting into where they shouldn't. The paper did catch fire a couple of times and I put it out simply by patting it with my leather-gloved hands. After tack welding the casters onto the frame I removed all the (partially burned) tape and paper and wrapped the casters again right before painting. One coat of red oxide primer and two coats of yellow quick dry enamel.

Future Make

Except for the general X shape, am still not satisfied with this second build. I was working within material constraints. I'd rather use 1/8" x 2" flat bars as the platform and then weld on 1/8 x 1" flat bars as vertical supports, thus forming a T section. And I find the 1" casters too small for ease of rolling and too flimsy for the heavy load. 1-1/2 to 2" diameter wheels would be far better. And instead of casters with mounting plates that have 4 holes for screws, I'd use something like these and have those vertical pins go under the LPG bottle to secure it in place on the dolly. And if it isn't yet obvious, the tack welds on the casters are absolutely godawful! They're hideous. I'd rather not resort to welding them unless they've got much beefier steel plates.

Subscribe to:

Comments (Atom)